end of arm tooling definition

End of arm tooling definition. End of arm tooling or EOAT is the field of robotic gripper technology.

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

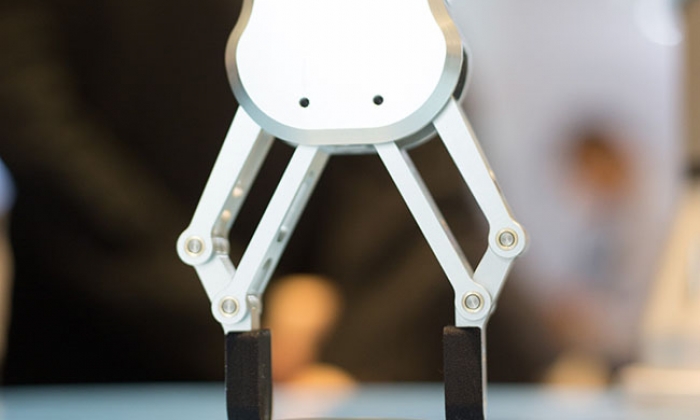

The end of arm tooling is a special type of light-weighted conformal and strong hand extension in the robots.

. The Ins Outs of End-of-Arm Tooling EOAT If youre interested in automating your food processing facility and integrating robotics one of the biggest considerations youll encounter is end-of-arm tooling. Other terms used include end arm effector end effector and head tool though these are more common in the automated assembly world. It has seven metal segments that are joined together with the help of six joints.

They are a diverse automation solution that can be customized to achieve many purposes across multiple industries and applications. A gripper is the mechanical or electrical End Of Arm Tooling EOAT device that enables the manipulation of an object. Sunday March 27 2022.

Light tools allow the arm to move faster and more efficiently and conformal tooling maximizes the contact surface. The end effector is the part of the robot that interacts with the environment. Grippers or end of arm tooling devices enable the manipulation of an object.

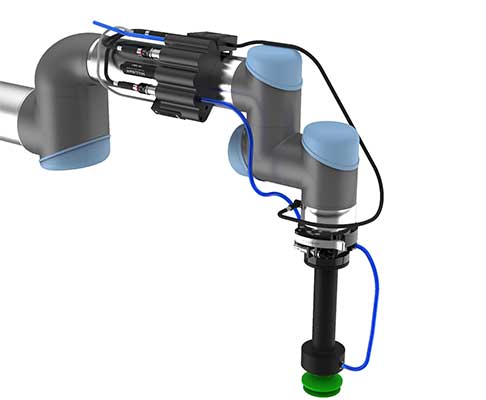

In robotics an end effector is a device or tool thats connected to the end of a robot arm where the hand would be. There are a wide variety from welders drivers grippers ladles riveter sprayers and more. The robot itself cant do any work without end-of-arm tooling EoAT such as grippers or sensors.

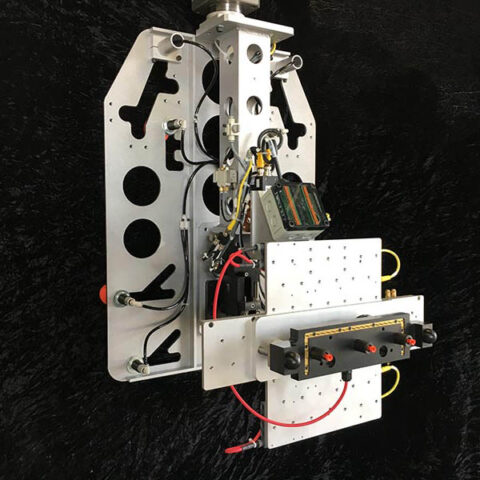

These components are also known as end effectors. Robotic Automation Systems End of Arm Tooling EOAT provides. The most common name in the molding world is end of arm tool and is usually abbreviated to EOAT.

Basically an end effector is the business end of the robot. The structure of an end effector and the nature of the programming and hardware that drives it depend on the task the robot will be. Simply put end-of-arm tooling EOAT ie the end effector is the device at the very end after the last axis of a robotic arm.

If youre looking into collaborative automation EoAT is the key to optimizing your processes and growing your business with greater flexibility higher output and improved quality. Rock Abrasion End Effector on Mars Rover Spirit. These components are collectively known as the end of arm tooling or EOAT.

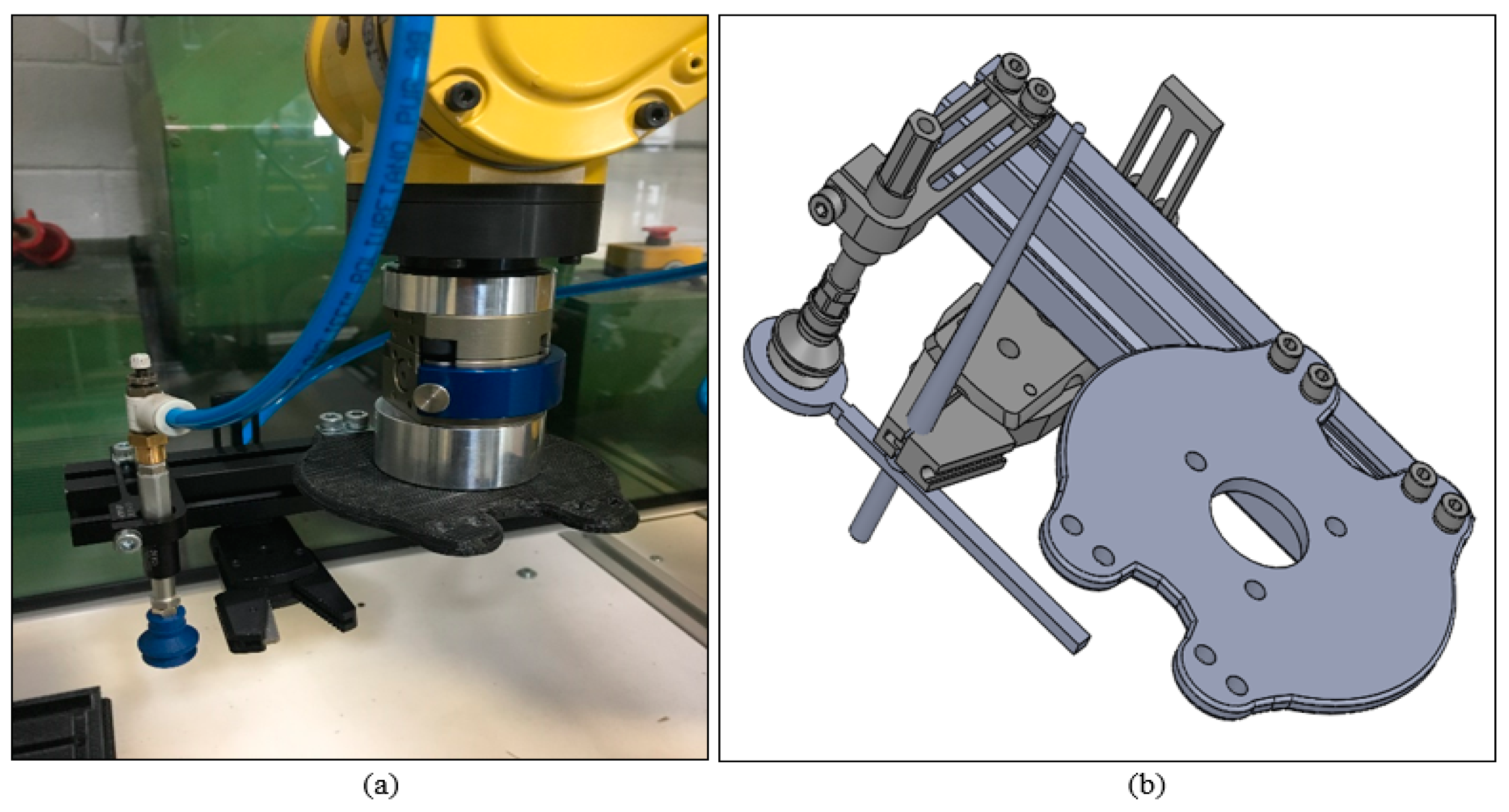

Precision mounting surfaces allow for the attachment of custom designed finger tooling. For example the welding torch on a robotic welding system. These dependable stable systems allow for quick and easy tool changes reducing downtime caused by adjusting manual tool changers or manually removing and installing equipment.

Lets look at the differences. End of arm tooling EOAT is a crucial aspect of robotic technology. Characteristics of End-Of-Arm Tooling 15.

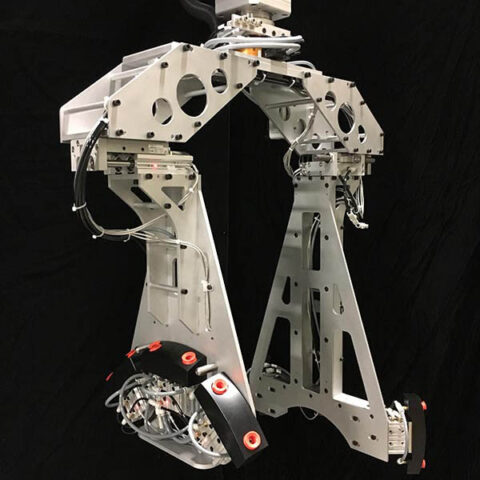

A robot gripper is an end-effector or sometimes called end-of-arm tooling that is used on industrial robots for material handling eg grasping holding lifting moving and controlling materials. Simulating the incredible engineering of the human hand. When it comes to end of arm tooling options for robotic arms and automation components there are three main categories.

It refers to the equipment that interacts with parts and components typically at the end of a robotic arm. Robot End Of Arm Tooling EOAT components Piab provides an extensive offering for all types of palletizing and de-palletizing operations no matter if you are looking for ergonomic handling equipment components and sub-systems to build your own End of Arm Tool or ready- to- use palletizing End of Arm Tool for industrial robots or collaborative robots. In this way the gripper itself becomes a measuring.

One could even say that there will be no automation advantages without at least one EoAT. The world of EOAT is full of innovative designs that have the same goal. End of Arm Tooling or the end effector is the core of the robot tool in which the robot component communicates with the environment at the end of a robotic arm.

Their robustly engineered construction and use of high quality components ensures long life and low maintenance. What Factors Influence The Design Of A Gripper. Some are as basic as a two-finger gripper while others are complex processes such as welders screwdrivers or self pierce rivet heads.

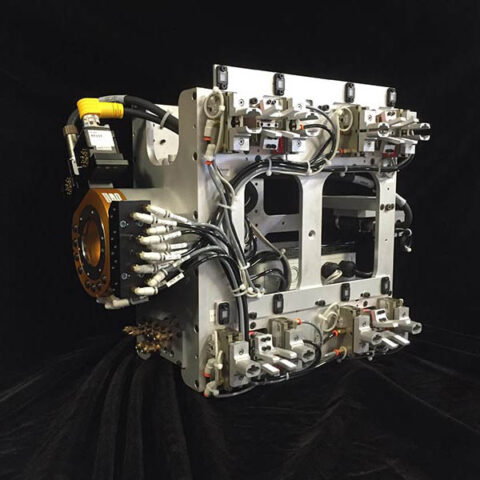

End Of Arm Tooling EOAT also known as effectors are the attachments of the robotic arm. Selecting the right gripper can make automation projects easier. Powered by electricity hydraulics pneumatics magnetics and vacuum these components are collectively known as the end of arm tooling or EOAT.

The computer takes the power to control the robot by rotating the motors joined to each joint. Our end of arm tooling EOAT grippers and robotic end effectors are custom designed and built for your specific application for increased speed and accuracy. The end-of-arms tools are a key robot component and differ from one application to another.

They range from simple two-fingered grippers for pick-and-place tasks to complex sensor systems for robotic inspection. Pronounced ee-oh-ay-tee not ee-oat. They make it easier for your robot to interact with the environment and do the work necessary to benefit from the robot application.

The end of every robot arm has a tooling attached to it to accomplish a specific job. Although it is also one of the most challeng. Grippers sensors and material tooling.

EoAT also known as end effectors - are crucial for unleashing the automation potential of collaborative robots. If you have ever tapped into the subject of collaborative robotics then you have most certainly encountered the terms end of arm tooling or EoAT. Most end effectors are mechanical or electromechanical and serve as grippers process tools or sensors.

There are 3 sections to EOAT. A Special End Effector Designed By NASA. EOAT is used in a variety of industries including automotive and medical.

These devices are the key to allowing robots to do their jobs and interact with their environment. Robot grippers are the physical interface between a robot arm and the work piece. End-of-arm tooling EOATthe hands at the end of industrial robot arms that enable industrial automation should be lightweight conformal to each unique part a robot manipulates and strong enough to move heavy parts.

The term End Of Arm Tool EOAT may also be used. End of Arm Tooling EOAT could be gripers for clamping the objects or tools for manufacturing operations. End of Arm Tooling simplifies the process of reconfiguring robotic end-effectors.

The end of arm tooling provides automation to the robot. Arc welding spot welding painting polishing grinding machining etc. End of arm tooling which is commonly known as end effectors are specific devices that are attached to the end of a robot arm which come in many shapes and forms.

This end-of-arm tooling EOAT is one of the most important parts of the robot.

What Is End Of Arm Tooling For Robots Onrobot

4 Robot End Of Arm Tooling Inlearc

4 Robot End Of Arm Tooling Inlearc

4 Robot End Of Arm Tooling Inlearc

End Of Arm Tooling Eoat By Robotic Automation Systems

End Of Arm Tooling Eoat By Robotic Automation Systems

Eoat Meaning Types Magnetic Gripper Manufacturer Hvr Mag

Eoat Meaning Types Magnetic Gripper Manufacturer Hvr Mag

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

Eoat Meaning Types Magnetic Gripper Manufacturer Hvr Mag

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

End Of Arm Tooling Robot End Effectors Millibar Robotics

End Of Arm Tooling Eoat By Robotic Automation Systems

What Is An End Effector And Or End Of Arm Tool Eoat Ferrobotics

Ansi Ria R15 06 2012 The Industrial Robot Safety Standard 2017 12 26 Ishn

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

End Of Arm Tooling Mechanical End Of Arm Tooling Pmmi Prosource

Ultimate Guide To End Of Arm Tooling Eoat Dek

Robotics Free Full Text 3d Printed End Of Arm Tooling Eoat For Robotic Automation Html